-

Lubrication and monitoring system in concrete mixer

For the lubrication of the whole concrete batching plant, domestic or imported oil are ok. For China brand, we recommend CHANGCHENG. For imported oil, we suggest Mobil, ESSO, SHELL. BP, etc. For the concrete mixer, there are 4 points to lubricate. The first three are important. 1. The shaft head sealed grease pump: Mobil NLGI 1 or NLGI 2 grease. 2. Reduction gear: Mobil GEAR629 3. Hydraulic station oil tank: Mobil DTE 25 4. Other lubrication points: hinge in the observation door, cylinder pivot point, jackstay in motor base plate, small grease needed every 2-4 weeks. Observe the oil level and oil quality through oil window: oil level should be in the 1/2-2/3 of the oil window. If oil level is too low, please replenish. If oil quality turns bad, please renew it. Please make sure that the air vent in the oil plug (oil filter point) is unobstructed. Otherwise, the air expansion in the oil tank will cause tank leakage. For both lubrication oil and grease, their viscosity will change as the...

-

concrete mixer starting system and normal operation mode

Since the power of concrete mixer is large, in order to reduce the impact to the power grid, the machine should starting by Y-△(star-delta starting). Besides, it should start with no load and start alternately with the inclined belt. According to the Current number in no-load and full-load, we can confirm if the machine is working well by checking the ampere meter on the manipulate platform. The empirical number of rated current of machine: Amotor power X2. If no-load, the Current is 1/3 A. For example, in HZS180 concrete batching plant, we use SICOMA 3m3. The total power of two driving motor are 110kw, rated Current is 220A. In no-load condition, the Current will be about 70A, and the current should be stable. The normal operating condition: no excessive vibration, no abnormal sound, no oil leakage, no leakage in discharging gate or shaft head. Voltmeter, ampere meter indicates as normal. The highest temperature during running should be less than 80 ℃, the maximum temperature rise...

-

HZS125 Concrete Batching Plant

HZS125 adopts modular structure design, which maintains convenient installation& removal and safe, comfortable operation, with good mixing effect and high efficiency. Besides, it adpots PLC automatic logical program control and host computer all-time tracking management, with safe and reliable operation and more facilitate maintaining. With fully-closed tower, aggregate conveying system and dedusting system can effectively reduce environmental pollution arising from dust and noise....

-

MHBT25-L2 Concrete Mixer Pump

HBT25-L2 Electric Mobile Concrete Mixer Pump is a very useful machine which definitely combines the features of traditional concrete pump and concrete mixer together. It can reach the function of feeding, blending, mixing and pumping First the pump gets into the mixing system, after that it enters into the pumping system. And then it is pumped to the construction spots with the help of conveying pipes. Thanks to its fully automated construction operating system, the whole process is finished in a very short time. As one of the most popular concrete conveying equipment, more and more customers become interested in it. Hot Sale in stock: HMC3.5 self-loading mixer - SICOMA Mixer - HZS60 Concrete Mixing Plant - DHBT40 concrete pump - HBT15 Concrete mixer and pump - DHBT15 Concrete mixing pump - Get quote or inquiry!...

-

Self-loading Mobile Concrete Mixer

Self-loading mobile concrete mixer is an equipment combined with concrete mixer truck and concrete mixing station. Raw material loading, weighting, mixing and discharging all rolled into one. It could not only be used to transport the concrete but also produce the concrete at site. ...

-

YHZS35 Mobile Batching Plant

YHZS35 concrete batching plant is kind of Mobile Concrete Mixing Plant developed by HAMAC Group, based on the advantage of many models in China and overseas and the advanced technology, combing the experience of HAMAC Group in the past years. The batching unit, aggregate conveying unit, water supplying and additive agent supplying system, scaling system, mixing system, electrical control system and pneumatic system are centralized in one trailerized chassis. It has the feature of instant trailing, instant stop, reasonable structure, well function, reliable working, convenient operation, accurate scale, particularly suitable for moving sites and construction site like road, bridge, dam, airport....

-

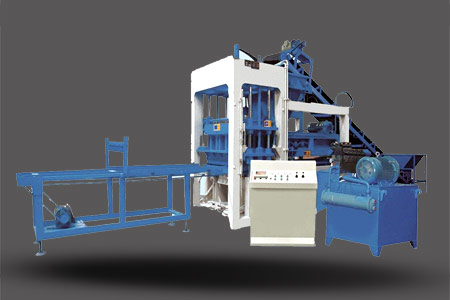

QT4-15B Block Making Plant

Uses high-dynamic proportional and directional valves, which automatically adjust the oil flow and pressure as per specific working requirements, to buffer the hydraulic cylinder when working; uses integrated high-pressure and soft oil pipes, with easy installation; 3) Uses multi-shaft rotating and compulsory feeding, which greatly improves the density and intensity of the blocks, and reduces the feeding time as well....

-

Belt Conveyor type Concrete Batching Plant

HZS series concrete batching plant is a plant which is forced and high efficiency, it is an ideal equipment to produce the commercial concrete which is used to produce plastic concrete, dry concrete and so on. Because of its high efficiency, it is being widely used in big and medium scale construction project, road and bridge, and the factories which produces the pre-fabricated concrete component....

-

HBT15 Electric Concrete Mixer Pump

As the name implies, the power system of electric concrete mixer pump machine is motor. Because using electricity is environmental and convenient, it is a popular choice for many people. In the past time, the construction subcontractor wanted to buy a concrete mixer to produce the concrete firstly, and then he also needed a concrete pump to deliver the concrete to the buildings. There will be two machines to finish this job. It required more people for the projects. In order to solve this problem and provide our customer with better solution. We researched and developed this concrete mixer with pump. You can finish all the work by the same machinery. It combined concrete mixer with concrete pump. When the concrete pump is working, the concrete mixer is also working. It will save your time to produce and deliver the concrete. After it is sold to the market, we get a positive response from our customers. Most of them said that it is really a revolution for the mixer and pump....

-

QT8-15 Automatic Block Making Plant

QT8-15 block brick making machines full automatic : It adopts the PLC operating system,and the action procedures lock with each other,which can guarantees the machine safely and dependablely in the operation procedure.Equipped with color face material feeding device,it could make various color face bricks,through-body Environmental protection bricks,road curb rocks,hydraulic blocks and sod bricks and so on. Multifunction in one machine.Changing molds can produce various kinds of specification porous bricks,standard bricks,hollow bricks,with a double material-feeding machine can produce all kinds of the colored road bricks,grassland bricks,and slope protection bricks etc....

Why Choose HAMAC?

Q: Are you a factory or trading company?

HAMAC: We are a company which include trade and industry. We have our own factory which has been manufacturing concrete machineries along with spare parts for 20 years offline.

Q: How about the quality control of your productions?

HAMAC:All of our products passed ISO9001:2000, some of them got CE Certificate. We have a very strict quality control system, all of our suppliers are selected strictly and carefully. We will take strict inspection

before the goods shipped.

Q: What do you think is the most competitive advantages when comparing with other suppliers?

HAMAC: HAMAC only present true information to all of our clients, HAMAC only provide our clients with high quality machines. Most of our clients are regular clients, it is a proof of our quality. And the new buyers

would like to repeat orders from us since we are not only sell goods but also services.

Q: How do you think the relationship between quality and price? Relationship between buyer and seller?

HAMAC:If you care about the quality, please respect its price. If you only care about the price, do not expect a good quality. Market price is well-known, the seller will not quote a higher and unreasonable price

to push away the buyer.

One deal, to make one new friend. Reputation is the most important thing. HAMAC will not destroy the reputation because of an order. We are pursuing long-time cooperation.

Solutions

Concrete Mixer

Self-loading Mobile Concrete Mixer

JS series Concrete Mixer

Self-loading Mobile Concrete Mixer

JZ series Concrete Mixer

JZR Diesel Driven Concrete Mixer

European Tech.Twin shaft Concrete Mixer

MP Planetary Concrete Mixer

Concrete Mixer with Pump

SICOMA Double Shaft Concrete Mixer

Products

Concrete Mixers

Concrete Batching Plant

Concrete Conveying Plant

Related Concrete Equipment

Concrete Block Making Plant

NEWS

- A Successfully Case about MP1000 Was Made with Mexican Customer

- HZS90 Concrete Mixing Plant and Loading Machine Were Shipped to Indonesia

- A set of concrete mixer with pump was delivered to Ecuador

- Concrete mixer with pump delivered to Saudi Arabia

- Two sets of Concrete mixer with pump arrived customer's site

- HBT08 Concrete mixer with pump ready for delivery

- Hot sale concrete placing boom delivered to Dubai

- HZS180 Being Installed in Mongolia

- Mobile Concrete Batching Plant YHZS75 Was Delivered

- Self-loading mobile concrete mixer ready for delivery

Get Quote

Get Quote Chat Online

Chat Online